Established in 2011 , Zhejiang Leasinder Technology Co , Ltd locates in the national level Hangzhou Yuhang Economic and Techologycal development zone in Zhejiang . Is a

China acrylic sheets manufacturers and wholesale acrylic sheets suppliers

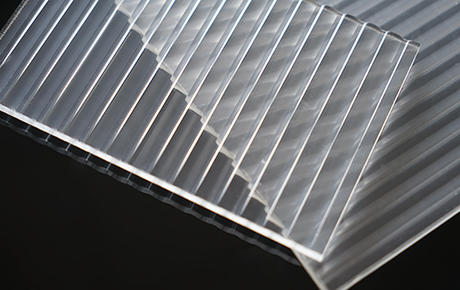

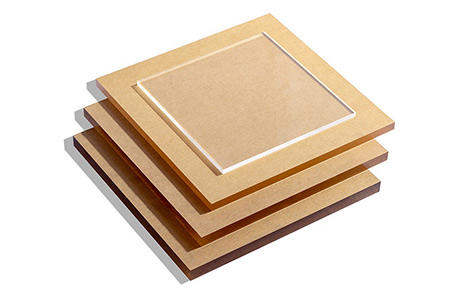

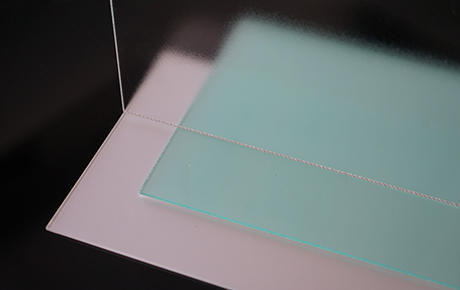

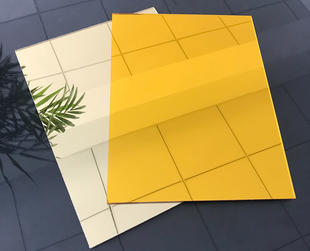

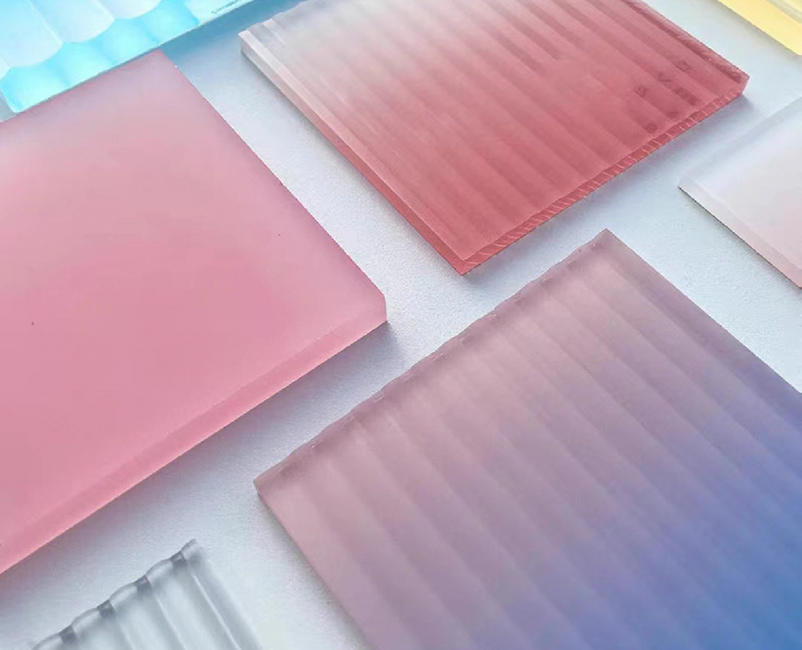

, our factory covers an area of 10,000m² , total construction area 22000m² It is KeyHi-Tech enterprises of National Touch Program . It has the title of " Municipal Technical research and Development Center”. It has been mainly engaging in the production , Process and sale of acrylic sheet ,acrylic mirror sheet , PS sheet , PS mirror sheet , OPP sheet , PET sheet , PC sheet , MS sheet, diffuser sheet , acrylic light guide plate-LGP , PMMA / PS / OPP / PET / MS / PC optical extruded clear sheet, colored sheet.

The company has been fully equipped. There are 5 extruded lines ,3cast lines, 3 sets of electroplating machines , dozens of laser cutting machines ,LGP printing machinary , sheet surface stiffened equipments and UV-pr inters.

General manager Mr . Guzuliang , here warmly welcomes all the clients from homeandabroad to visit and give guidance , to discuss cooperation and seek common development .

English

English 中文

中文 Español

Español