Clear Acrylic Sheet does require special packaging materials to protect it during transportation to prevent it from being scratched, cracked, deformed or otherwise damaged during transportation. Because the clear acrylic sheet has a softer surface, it is easily scratched by external impact or friction. At the same time, it is brittle and easily cracked when it is hit or pressed. Therefore, reasonable packaging design and material use are essential.

Foam materials (such as foam boards, foam plastics, bubble films, etc.) are one of the most commonly used packaging materials to protect clear acrylic sheets. It can effectively alleviate impact and vibration and prevent the surface of the sheet from being damaged or cracked. Specific methods include:

Wrap the surface of the acrylic sheet with bubble film, which can provide better cushioning and reduce friction.

For larger acrylic sheets, you can use foam boards to wrap the sheet around, which can not only avoid scratches, but also reduce the impact when it is subjected to external pressure.

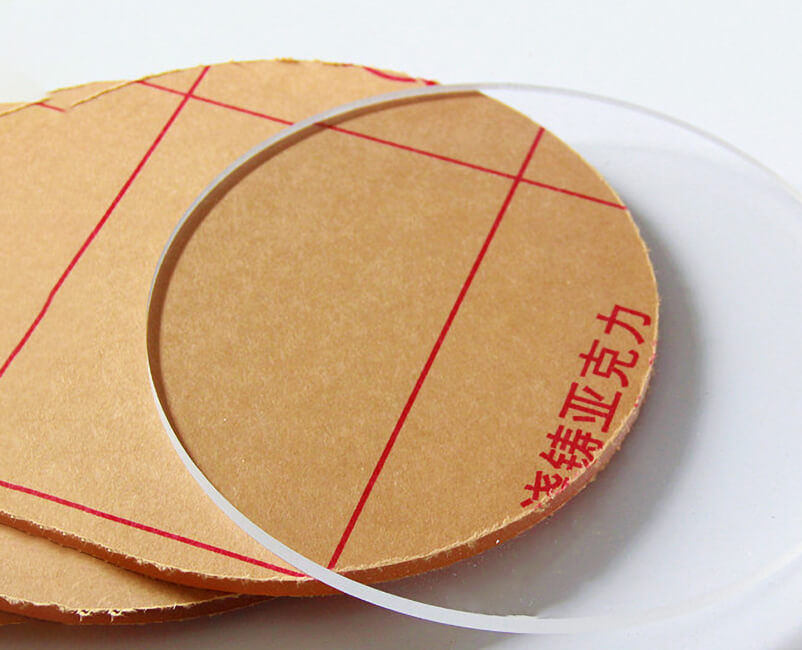

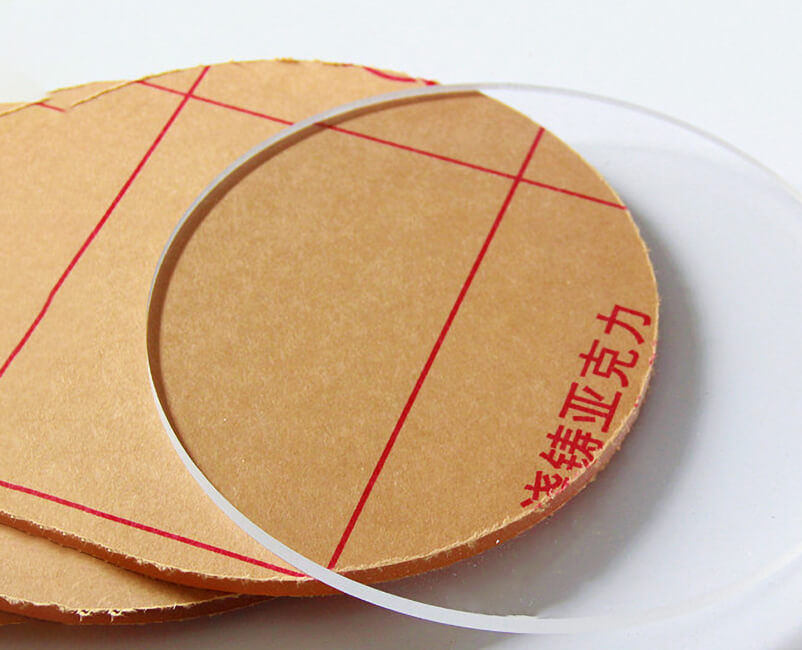

Clear Acrylic Sheet is often covered with a protective film to prevent scratches or dust during transportation. The protective film can effectively keep the surface of the sheet clean and intact during transportation. Usually, Clear Acrylic Sheet will have a protective film on one or both sides (depending on the manufacturer's requirements) to ensure that the surface of the sheet will not be scratched during transportation and installation.

The protective film is usually applied before transportation, and the film layer can prevent minor scratches. After transportation, the film layer can be easily torn off without leaving any residual glue.

For larger sizes or large quantities of Clear Acrylic Sheets, cardboard or wooden boards can be used for reinforced packaging. These reinforcements help maintain the shape of the acrylic sheet and prevent the sheet from bending or deforming during transportation.

Combine Clear Acrylic Sheet with cardboard, which can cover the edges of the sheet and protect the sheet from friction.

For large-sized acrylic sheets that are particularly vulnerable to damage, wooden box packaging is the best choice. Wooden boxes can provide the strongest protection against squeezing or impact during transportation.

During transportation, it is crucial to ensure that the acrylic sheet can be placed stably. If the number of acrylic sheets is large or the size is large, a reasonable stacking method can be adopted and fixed by bundling, strapping, etc. Ensure that the sheets do not slide, tilt or collide with each other during transportation.

Avoid stacking acrylic sheets directly together. You can use soft pads, paper pads or foam boards between each layer to prevent friction or collision between the sheets.

Use strapping tape or wooden frames to fix the package to ensure that it will not loosen or shake during transportation and reduce the impact on the sheet.

Acrylic sheets are sensitive to temperature changes. Too high a temperature may cause the sheet to deform, while too low a temperature may make it fragile and easy to crack. Therefore, care should be taken to avoid environments with too high or too low temperatures during transportation. For long-distance transportation, especially cross-season transportation, temperature control measures may need to be considered.

Avoid exposing Clear Acrylic Sheet to extreme temperatures, especially in high or low temperature environments. The compartment of the transport vehicle should be kept at a constant temperature as much as possible.

When stacking Clear Acrylic Sheet, avoid pressing heavy objects directly on the acrylic sheet. Although clear acrylic sheets are strong in pressure resistance, excessive pressure for a long time may cause the sheet to deform or crack. Therefore, try to avoid stacking heavy objects on the acrylic sheet during transportation.

Clear Acrylic Sheet does require special packaging materials to protect it from damage during transportation. Common protective measures include the use of bubble film, foam materials, cardboard or wood reinforcement, protective film, temperature and humidity control, and proper stacking and fixing. Through these measures, it is possible to effectively avoid scratches, cracks, deformations, etc. during transportation, ensuring that the acrylic sheet remains intact when it arrives at its destination.

English

English 中文

中文 Español

Español