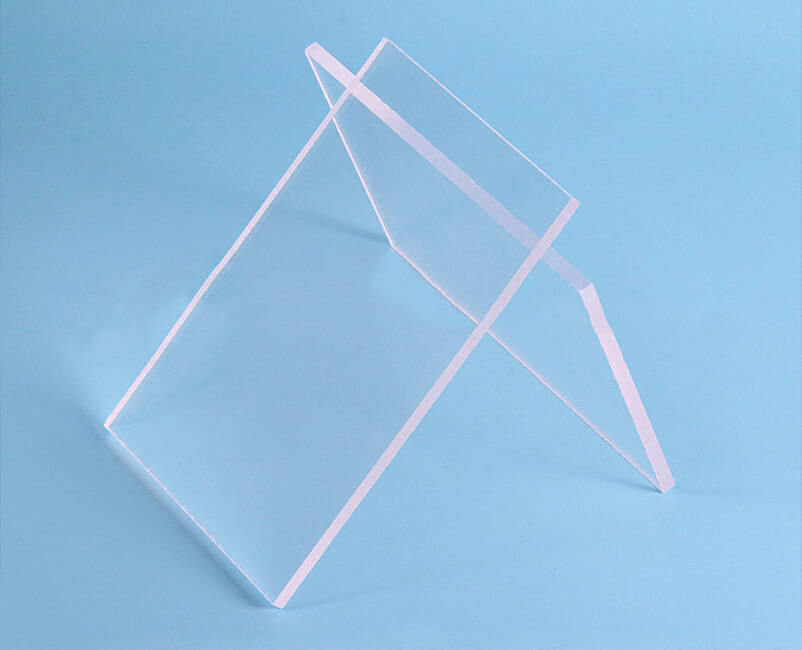

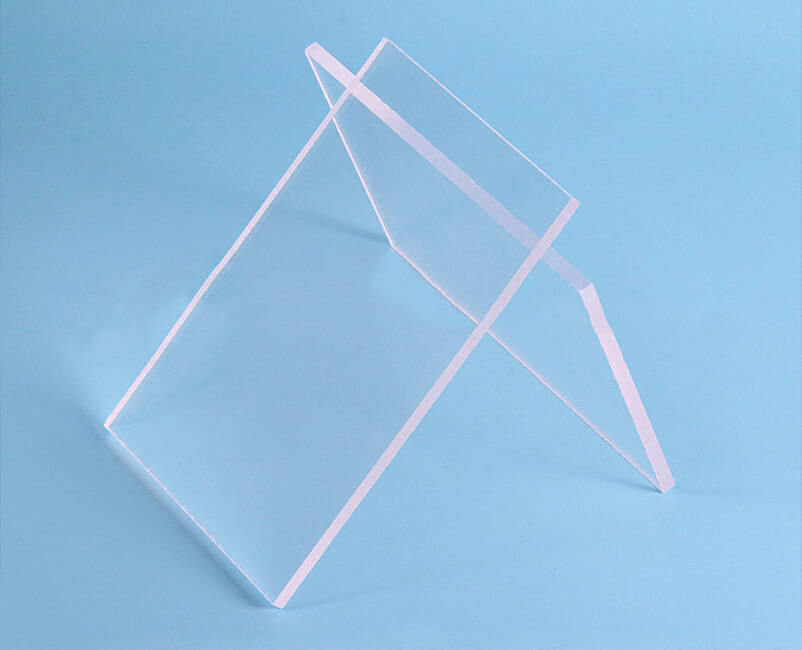

The production process and quality control of PS Sheet are crucial in ensuring its performance and stability. The design of the production process, raw material selection, equipment configuration, and quality monitoring all directly affect the final quality of PS sheet, including its physical properties (such as transparency, strength, heat resistance, etc.), surface quality, and processing performance. The following are some key elements of PS sheet production process and quality control and their role in ensuring performance and stability:

The production process of PS sheet generally includes the following main steps:

The main raw material of PS sheet is polystyrene (PS) resin, which is usually mixed with additives (such as antioxidants, plasticizers, colorants, UV inhibitors, etc.) to improve performance and meet the needs of different applications. The choice of raw materials directly affects the characteristics of the final sheet.

After the polystyrene resin is melted, it is pressed into sheets through an extruder. The temperature, pressure, speed and other parameters of the extruder need to be precisely controlled to ensure that the raw materials are fully melted and extruded evenly.

After the PS sheet comes out of the extruder, it usually enters a cooling zone (such as a cooling roller or a water tank) to reduce its temperature and shape it. Controlling the cooling rate is very important for maintaining the dimensional accuracy and surface smoothness of the sheet.

For some PS sheets that require higher performance or special purposes, the thickness, strength and other properties of the sheet may be further adjusted through calendering or stretching processes.

The produced PS sheets are cut into the required size and packaged after quality inspection. The packaging process also needs to prevent the surface of the sheet from being damaged to ensure that the product maintains good quality when it is delivered to the customer.

During the production process, there are multiple links that need to be strictly controlled to ensure the quality and stability of the PS sheet:

During the extrusion process and cooling process, temperature and pressure are key factors affecting the quality of PS sheets. Too high temperature may cause material degradation or discoloration, while too low temperature may cause poor fluidity and rough surface of the sheet. Temperature control needs to be achieved through a precise temperature control system to ensure that the molten PS resin remains within the appropriate processing range.

The temperature control system of the extruder is usually divided into multiple temperature zones, and the temperature of each temperature zone needs to be precisely adjusted. A reasonable temperature range can ensure good melting of the raw materials and avoid physical property degradation caused by overheating.

Pressure control during extrusion is essential to ensure the consistency and surface quality of the sheet. Too high pressure may cause excessive stretching or unevenness of the sheet; too low pressure may cause poor material flow and affect the quality of the sheet.

During the extrusion and cooling process, the thickness and size of the PS sheet need to be precisely controlled. This is usually achieved by the following methods:

Use laser measurement, electronic ruler or other online measurement equipment to monitor the thickness of the sheet in real time. Automatically adjust the parameters of the extruder or cooling system based on real-time feedback to ensure uniform thickness of the sheet.

Use high-precision cutting equipment to ensure that the length and width of the sheet meet customer needs and industry standards.

The surface quality of PS sheet is an important indicator that customers pay attention to. Unsmooth surface, bubbles or impurities will affect the beauty and application performance of the sheet. In order to ensure surface quality, strict control is required during the production process:

During the extrusion and cooling process, ensure that the production environment is clean and reduce dust, impurities and moisture contamination, which may affect the smoothness of the sheet surface.

Uneven cooling speed can cause wrinkles, depressions or stretch marks on the sheet surface. Therefore, the speed and uniformity of the cooling process are critical. Control the temperature and speed of the cooling roller to ensure a smooth and flawless sheet surface.

In order to improve certain properties of PS sheets (such as UV resistance, oxidation resistance, antistatic, impact resistance, etc.), various functional additives are usually added to PS resin. During the production process, the ratio and dispersibility of additives have a huge impact on the performance of the final product.

The proportion of additives needs to be accurately formulated before production to ensure that they are evenly mixed. This is usually achieved through high-precision metering equipment to ensure that each batch of PS sheets has consistent performance.

The dispersibility of additives will also affect the performance of the sheet. By adjusting the speed of the mixing equipment, mixing time and other parameters, ensure that the additives are fully and evenly distributed in the PS resin.

The production process and quality control of PS sheets are closely linked. By reasonably controlling factors such as temperature, pressure, formula, production speed, additives, etc., it can be ensured that the PS sheet has stable physical properties and a long service life. Therefore, the comprehensive use of modern production processes and quality control methods is the key to ensuring the performance and stability of PS sheets.

English

English 中文

中文 Español

Español